YangWangU9 Create the most powerful supercar in the pure electric era

YangWang U9 opens the era of pure electric super sports cars.

Supercars are the perfect interpretation of speed. In the extreme competition of speed, the endless pursuit and breakthrough of performance have created the most powerful supercar in the pure electric era.

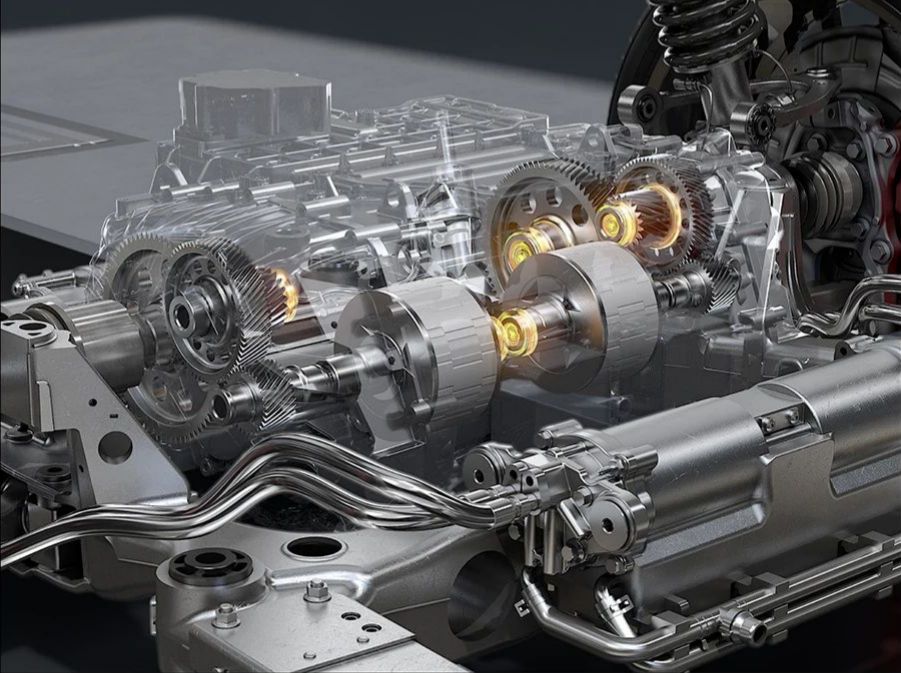

01 YiSiFang Empowerment: Beyond the Power Performance of V12 Engines

1. The peak power of four motors is as high as: 960kW

2. The maximum horsepower of the vehicle exceeds 1300PS

02 Achieving a driving experience like flying close to the ground

The world's original dual-motor and dual-electronic control deeply integrated design adapts to sports car aerodynamics and lightweight design. The size is more compact and the center of gravity is lower. It establishes the super sports car's extremely impactful dive posture and low-lying shape, which is more suitable for the track. Extreme driving.

03 When driving on the track, control accurately and still maintain the ideal state in corners.

When challenging on the track, powerful and precise performance control is required. YiSiFang distributes optimal torque to each wheel independently. At the moment of cornering, maximize the use of ground adhesion to increase the extreme cornering speed on the track. In the actual test on the track, the instantaneous maximum lateral acceleration of YangWangU9 reached 1.7g.

04 Efficient Thermal Management System

1. Silicon carbide electronic control, the highest transmission efficiency reaches 99.8%. Using a more efficient silicon carbide electronic control, the motor uses ultra-thin low-iron loss silicon steel sheets and high-temperature-resistant permanent magnets to improve motor efficiency, reduce heat loss, and improve the motor's temperature resistance.

2. Dual electronic oil pumps provide more accurate temperature control. Each oil pump independently controls the oil cooling of a motor, achieving intelligent control of the cooling oil volume of each motor.

3. Innovative design of three sets of thermal management systems for large, medium and small cycles to ensure cooling performance requirements in different scenarios.

4. Optimize the motor's magnetic circuit and select permanent magnets with higher temperature resistance and stronger demagnetization resistance, which can withstand temperatures up to 200°C to ensure the safety and performance of the electric drive system.

5. 12 sets of aerodynamic kits to comprehensively improve heat dissipation performance. 12 sets of aerodynamic kits and "space-time tunnel" air duct layout help the braking system dissipate heat and improve braking stability.

The above is the full content of YangWangU9 Create the most powerful supercar in the pure electric era