Detailed disassembly and analysis of the BYD Yuan (Atto 3)

Recently, a certain laboratory conducted a detailed disassembly of the BYD Yuan, indicating that the field of disassembly has expanded from phones and computers to new energy vehicles. This is also the first time that the Haitong Automobile Laboratory has disassembled an electric car.

This vehicle is BYD's first mass-produced model based on the e-platform and has milestone significance.

It is reported that the disassembled vehicle in the laboratory is the 2018 BYD Yuan EV360, manufactured by BYD Auto Industry Co., Ltd., with a manufacturing date of September 2018. The model is the Intelligent Connected Cool Edition in white, with a maximum allowable total mass of 1,870 kg.

The total acquisition cost of the vehicle is 103,400 yuan, including the vehicle's post-subsidy price of 99,900 yuan in August 2018 in the Beijing area, 3,000 yuan for vehicle insurance, and 500 yuan for license plate registration.

The BYD Yuan EV360, as the first pure electric vehicle model based on BYD's e-platform, was the first BYD model to exceed 10,000 units in monthly sales. With a price of under 100,000 yuan, it achieved over 20,180 orders in its first month after its launch in May 2018, and its cumulative sales exceeded 10,000 units in the first three months. In January 2019, the monthly sales volume exceeded 10,000 units, reaching 10,093 units, becoming the first BYD model to exceed 10,000 units in monthly sales. As of April 2022, the cumulative sales of the BYD Yuan EV have surpassed 174,000 units.

The overall dimensions of the vehicle are 4,360mm in length, 1,785mm in width, 1,690mm in height, and a wheelbase of 2,535mm. The front track is 1,525mm, and the rear track is 1,535mm. The vehicle body is made of steel. Among the BYD Yuan series, the Yuan PLUS chassis uses 85% high-strength steel, while the general 150,000-yuan level cars usually have 60-70%. Among them, 55% is ultra-high-strength steel, and 11% is hot-formed steel with a tensile strength of 1,500 MPa.

The report from the Haitong Automobile Laboratory presents every component of this electric vehicle in detail, including body structural parts, chassis, seats, wiring harnesses, multimedia systems, combination instruments, thermal management systems, battery systems, electric drive systems, and more, analyzing the exterior, handling, safety, cost-effectiveness, and range of the BYD Yuan.

Regarding the range of the BYD Yuan, the team believes that with a full charge of 42 kWh, it takes about 7 hours for slow AC charging to reach full capacity, and 3.5 hours to charge from 25% to 80%. DC fast charging has a power of about 40 kW and can charge up to 80% in 0.5 hours. In the summer, with the air conditioning on and in normal mode, it can run about 290 km, which is in line with the official range. The vehicle is more energy-efficient in the summer, but in the winter, it consumes more power. If the air conditioning is not turned on in the winter, the windows fog up, affecting visibility. However, once the air conditioning is turned on, the battery level drops rapidly. The use of cruise control and other functions has a significant impact on the range.

Let's take a closer look at the battery system and electric drive system of the BYD Yuan.

01

Battery System

① Battery System - Battery Pack

The Yuan EV adopts an independent aluminum tray for the battery pack, which is installed under the chassis. The battery utilizes lithium-ion cells with a capacity of 43.2 kWh. The energy density of the battery pack is 127 Wh/kg, and all components are manufactured by BYD.

② Battery System - The interior of the battery pack is insulated and protected by asbestos insulation pads.

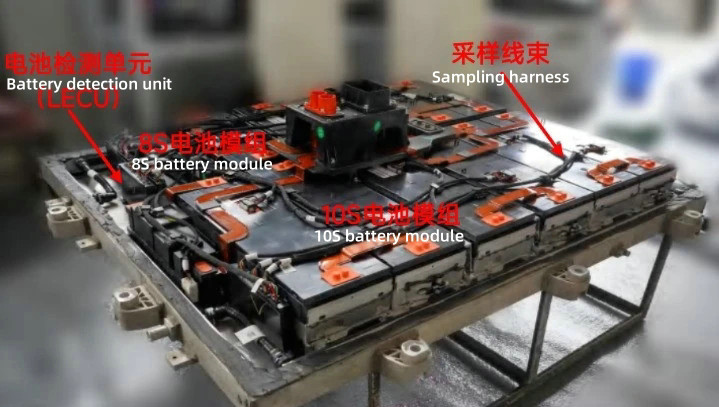

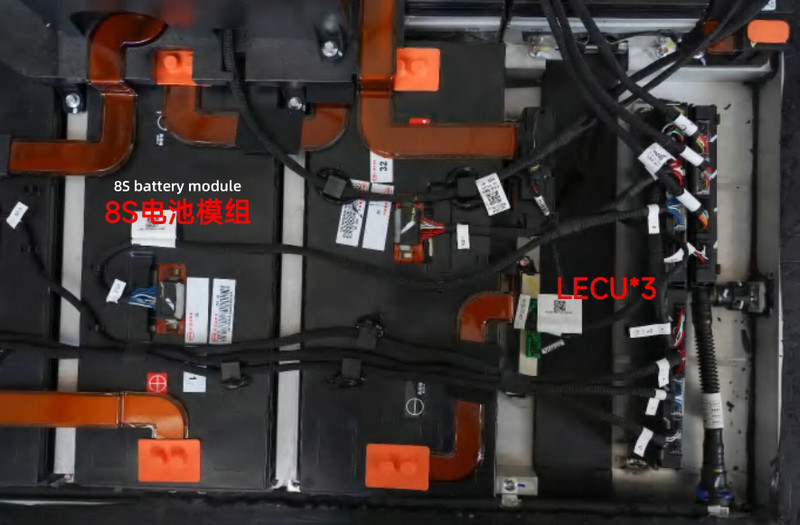

The battery pack of the Yuan EV360 has a total capacity of 43.2 kWh, consisting of 11 serially connected battery modules. Among them, 6 modules are connected in series with 10 cells each, and 5 modules are connected in series with 8 cells each. Thus, the battery pack is composed of a total of 100 cells.

③ Battery System - Cells and Modules

The battery pack utilizes individual cells with a capacity of 120 Ah for the lithium-ion battery. The rated voltage of each individual cell is 3.6V. The dimensions of the individual cell are 173 * 122.5 * 50mm.

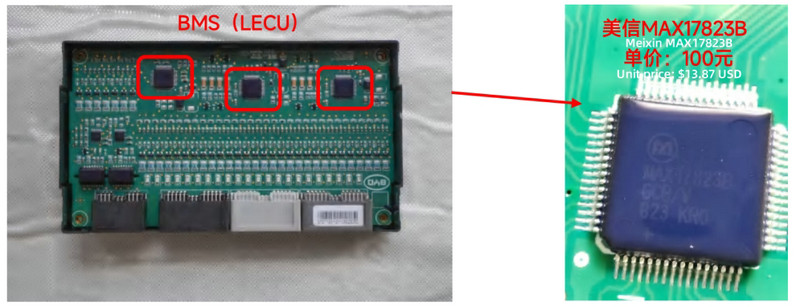

④ Battery System - BMS CECU

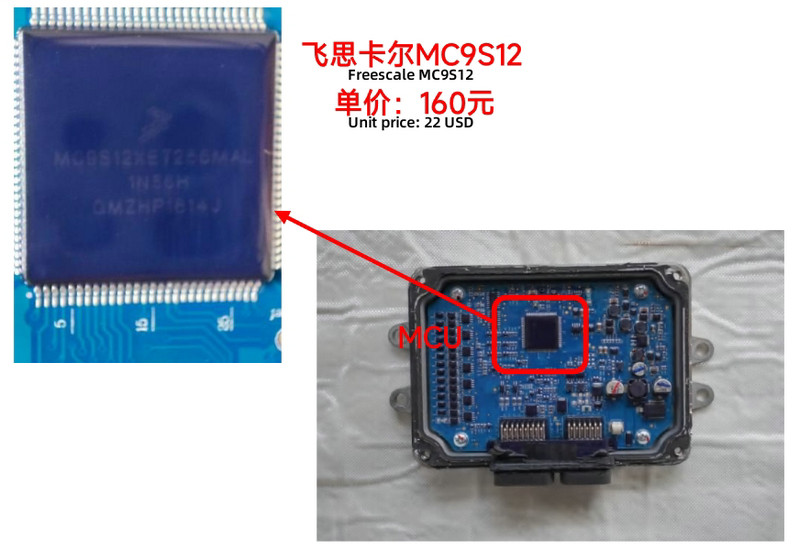

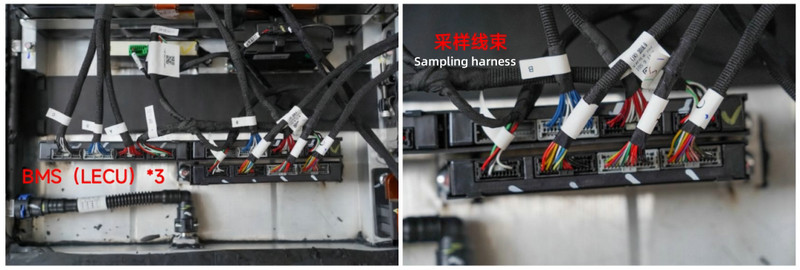

The BMS (Battery Management System) of the battery pack adopts a distributed architecture, including a Central Electronic Control Unit (CECU) located outside the battery pack and 3 Local Electronic Control Units (LECU) located inside the battery pack. The CECU utilizes Freescale's MC9S12XET256MAA (HCS12 series) as the main controller, responsible for monitoring the battery's state of charge (SOC), temperature, state of health (SOH), and other parameters.

⑤ Battery System - BMS CECU

Inside the battery pack, there are 3 LECUs, each corresponding to the sampling data of 11 battery modules.

The main function of the LECUs is to collect primary status information from the battery modules, including the voltage of each series-connected cell and the temperature data measured by temperature sensors within the modules. The data acquisition IC chip used by the LECUs is Maxim's MAX17823B.

02

Electric Drive System

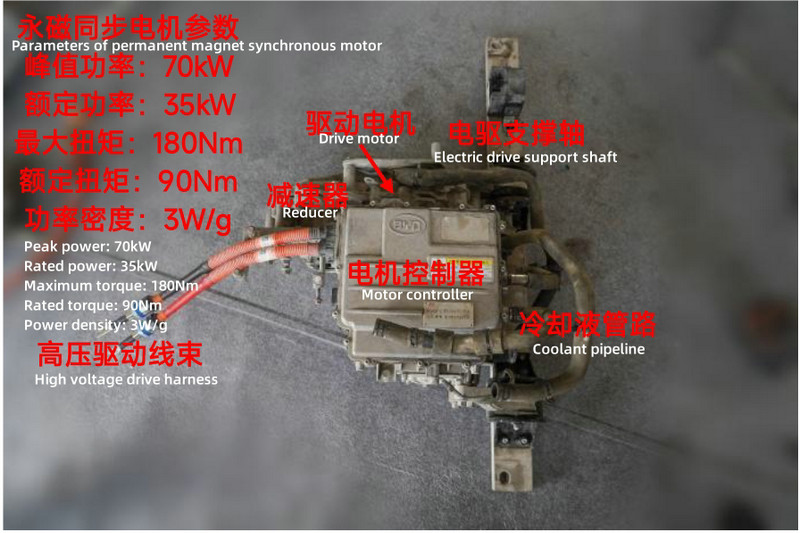

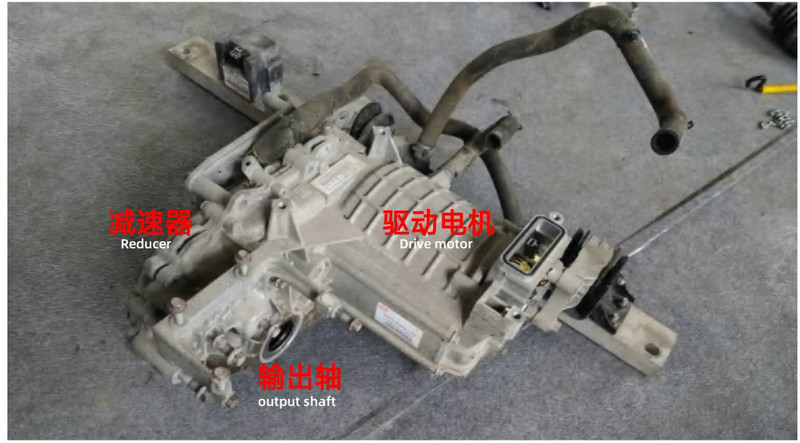

The Yuan EV adopts an integrated three-in-one electric drive assembly, which combines the motor, reducer, and controller. The core components of the electric drive assembly are all manufactured by BYD.

① Electric Drive System - Motor, Reducer

The motor utilizes a single-motor configuration and is a permanent magnet synchronous motor with a peak power of 70 kW and a rated power of 35 kW.

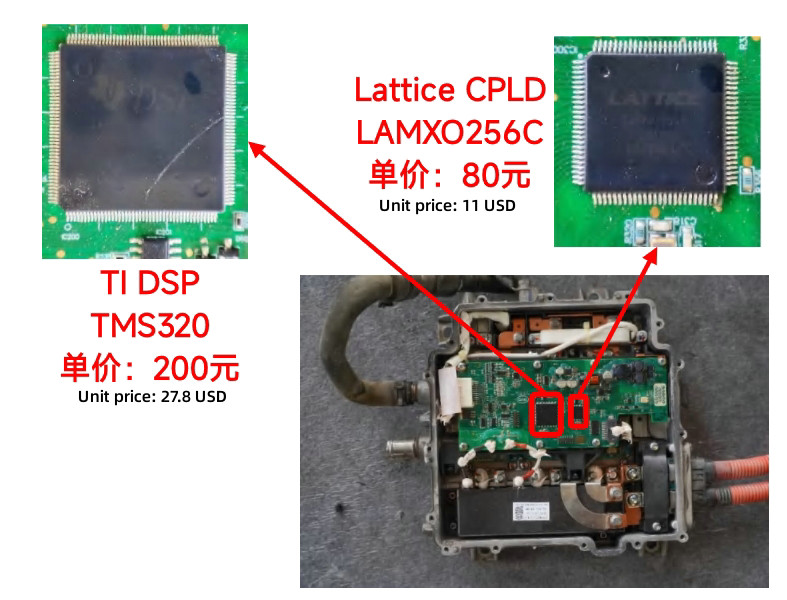

The motor controller uses TI's DSP (Digital Signal Processor) chip TMS320 in conjunction with Lattice's CPLD (Complex Programmable Logic Device) chip LAMXO256C.

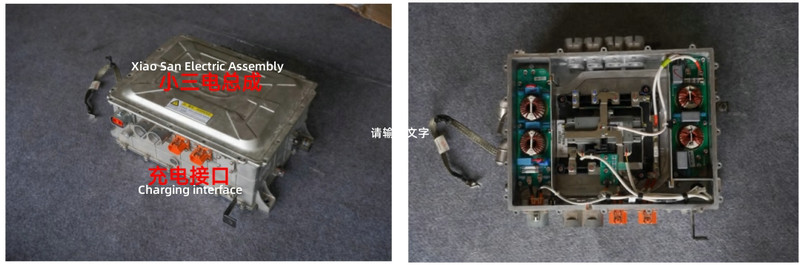

② Small Three-in-One Module

The Yuan EV adopts an integrated small three-in-one module, which integrates the On-Board Charger (OBC), DC-DC converter, and Power Distribution Unit (PDU) in a single module.

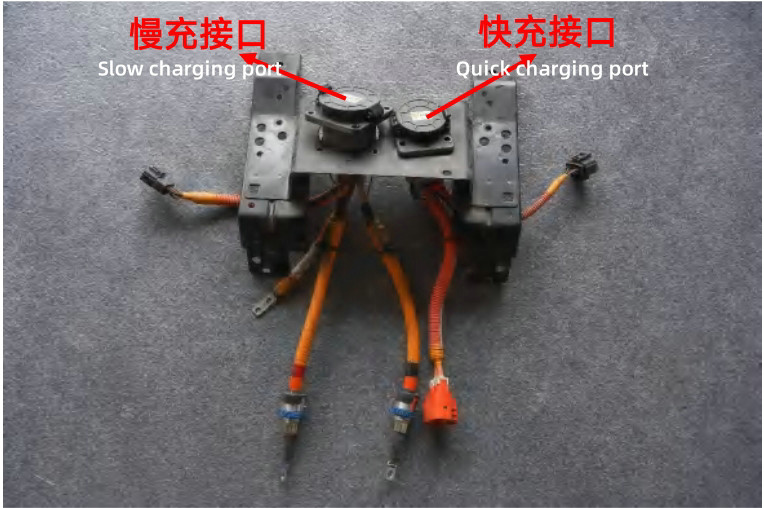

The charging port is located at the front of the vehicle and is divided into a 6.6 kW slow charging interface and a 60 kW fast charging interface. It supports 7 hours of slow charging or 0.5 hours of fast charging (up to 80% SOC).

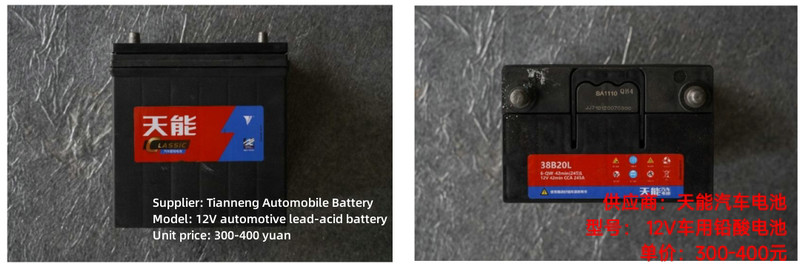

③ Start-Stop Battery

The 12V low-voltage system of the Yuan EV still utilizes a lead-acid battery, specifically the 38B20L from TianNeng. The lead-acid battery primarily supplies power to the low-voltage system and can be charged by the high-voltage system through the DC-DC converter.

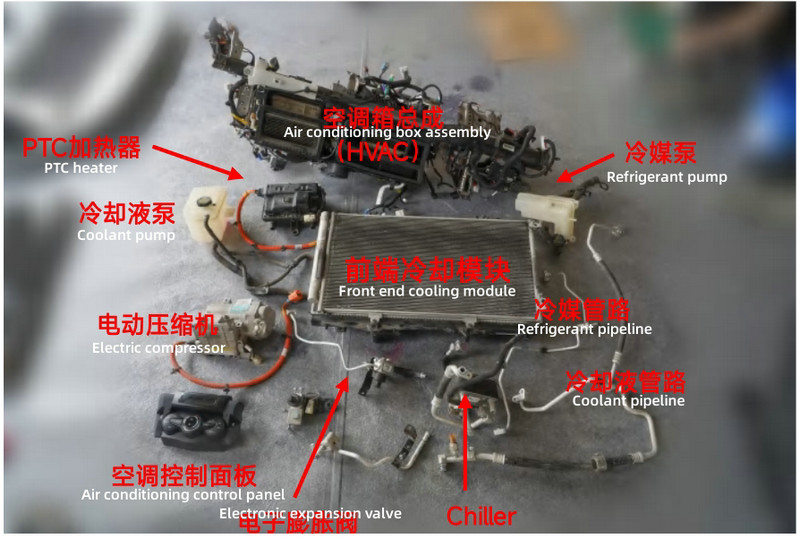

④ Thermal Management System

The vehicle's thermal management system adopts a traditional air conditioning cooling + PTC heating method. The overall system includes the air conditioning cooling system, PTC heating system, cooling fluid/refrigerant pipelines, and control panel.

⑤ Air Conditioning Cooling System

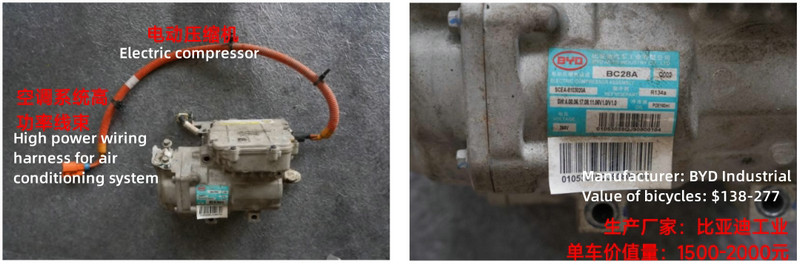

A typical air conditioning cooling system consists of core components such as an electric compressor, electronic expansion valve, and condenser/evaporator. The compressor is the "heart" of the air conditioning system. Its function is to draw in and compress the low-temperature and low-pressure gaseous refrigerant from the low-pressure side, raising its temperature and pressure. It then pumps the high-temperature and high-pressure gaseous refrigerant into the high-pressure side, completing a reciprocating cycle. It is a critical component that connects the low-pressure and high-pressure sides of the air conditioning circuit. The manufacturer is BYD Industry, and the unit value ranges from 1500 to 2000 yuan.

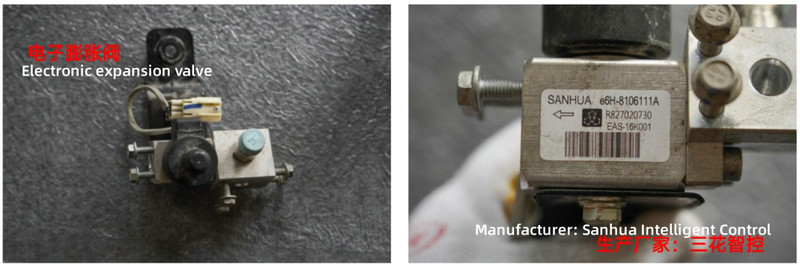

The expansion valve, also known as a throttle valve, is a critical component in the air conditioning system. It is positioned between the condenser and the evaporator in the basic circuit of the air conditioning system. Its function is to throttle the medium-temperature and high-pressure liquid refrigerant into a low-temperature and low-pressure liquid state (wet vapor), while controlling the flow rate of the refrigerant to prevent it from being too high or too low. In contrast to the compressor, the expansion valve is a key component that connects the high-pressure and low-pressure sides of the air conditioning circuit.

⑦ Radiator Assembly (Front Cooling Module)

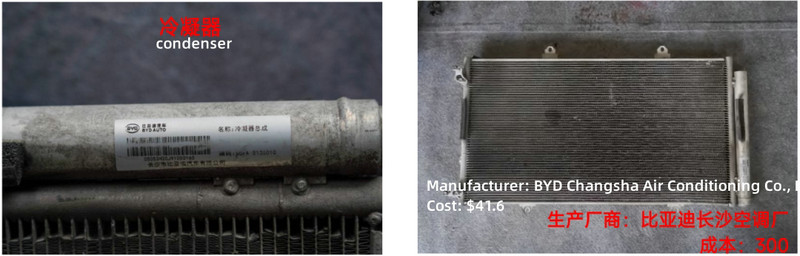

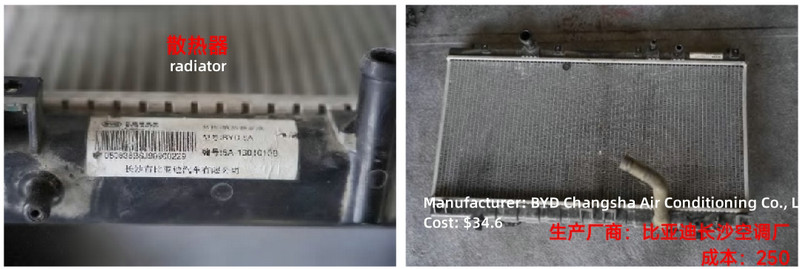

The radiator assembly (front cooling module) is located at the front of the vehicle and includes the condenser in the refrigerant circuit, the radiator in the cooling fluid circuit, and an electric fan.

The condenser is a component in the air conditioning circuit that exchanges heat with the outside.

The radiator is a component in the cooling fluid circuit that exchanges heat with the outside.

The electric fan accelerates the airflow rate through the radiator module, thus improving the efficiency of heat exchange.

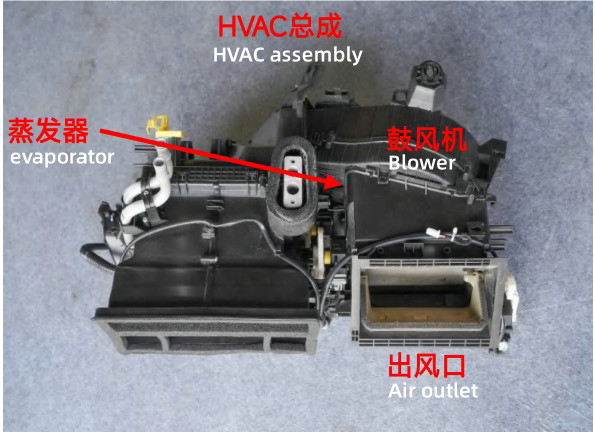

⑧ HVAC Assembly (Heating, Ventilation, and Air Conditioning)

The HVAC assembly is the interior module of the air conditioning system. Its main components include the evaporator, blower, and controller, which work together with external air outlets to supply air to the cabin.

⑥ Battery Thermal Management System

The battery's thermal management system needs to provide both heating and cooling for the battery pack. The heat exchange with the battery is primarily achieved through a water-cooled plate inside the battery box. The main intermediary for energy transfer between the battery pack and the outside environment is the battery cooler (chiller), which combines the functions of an evaporator and a heat exchanger.

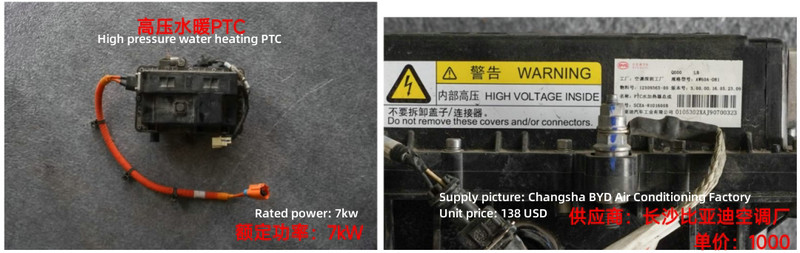

⑦ Water-Heating PTC Heating System

This vehicle adopts a PTC heating system, which uses PTC thermistor components as the heat source. It utilizes the current thermal effect.

The heat transfer mode is water heating, which means using the cooling fluid pipeline in conjunction with the blower to provide cabin heating. The same pipeline is shared with the cooling mode of the battery heating circuit.

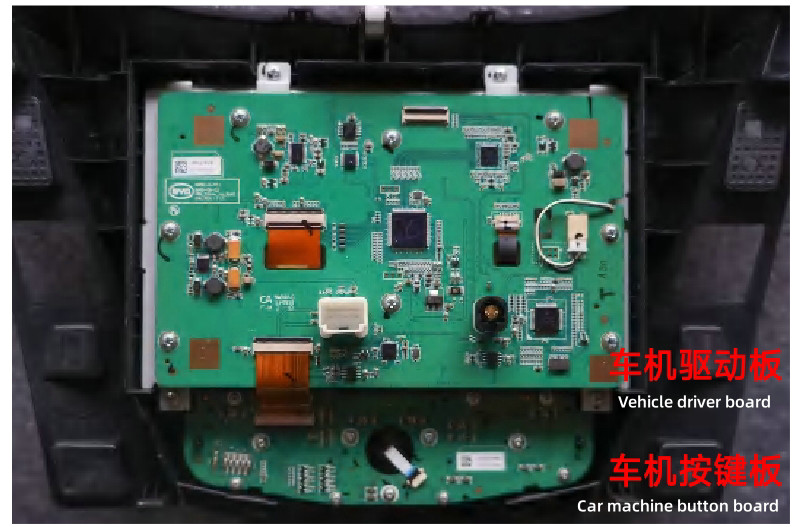

⑧ Multimedia System

The Yuan's multimedia system consists of a central control unit and a vehicle screen. The screen is an 8-inch LCD screen, and the entire system is independently developed and designed by BYD.

⑧ After disassembling the multimedia system, it includes two main PCB boards:

A PCB board behind the 8-inch screen.

B The host has two layers of PCB boards.

The PCB board behind the 8-inch screen includes the driver board for the vehicle screen and the button board corresponding to the buttons below the vehicle screen.

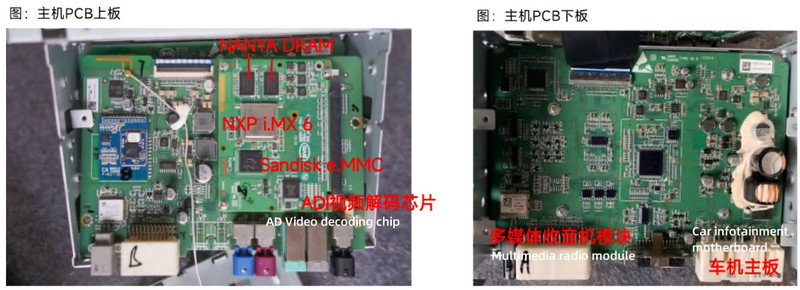

The PCB boards inside the host include:

A Upper board: Core chips include NXP i.MX6, Sandisk e.MMC, NANYA DRAM, and ADI video decoding chips.

B Lower board: It is the mainboard of the multimedia system, including the multimedia radio module, etc.

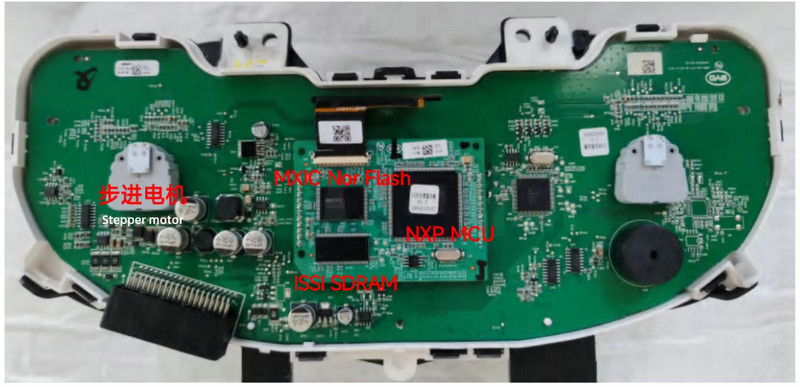

The core chips in the instrument cluster controller include NXP MCU, ISSI SDRAM, MXIC Nor Flash, etc.

⑨ Lighting Fixtures

BYD has two front headlights, with individual dimensions of 703020cm and a total weight of 4.25KG per headlight. According to parts distributors, the estimated value of a single front headlight is about 1200 yuan.

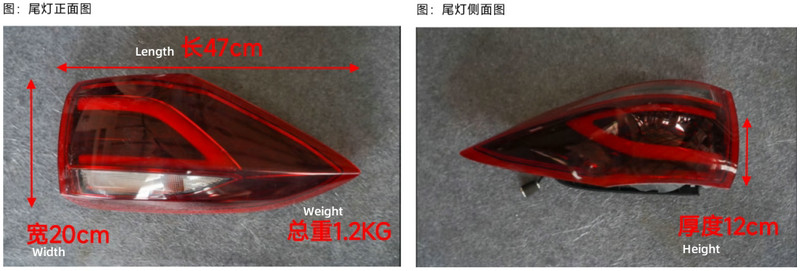

BYD has two rear taillights, with individual dimensions of 472012cm and a total weight of 1.2KG per taillight. According to parts distributors, the estimated value of a single taillight is about 450 yuan.

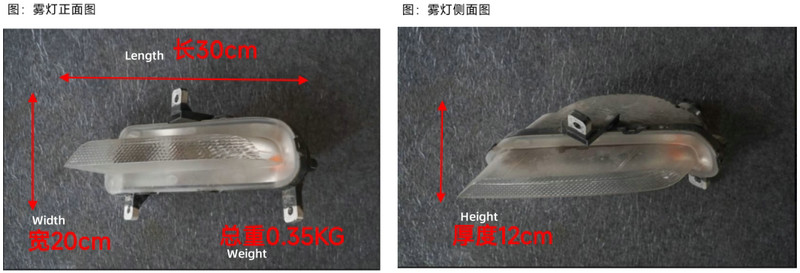

BYD has two fog lights, with individual dimensions of 302012cm and a total weight of 0.35KG per fog light. According to parts distributors, the estimated value of a single fog light is about 100 yuan.

03

Conclusion

BYD represents a microcosm of the upgrading and transformation of China's manufacturing industry. This 2018 "Yuan" model, whether in terms of aesthetics or level of intelligence, is far from comparable to today's BYD vehicles. However, by dismantling this model, we can provide investors who are new to the industry with a more intuitive understanding."

The above is the full content of Detailed disassembly and analysis of the BYD Yuan (Atto 3)