How safe is Tesla?

Tesla’s design puts safety first and provides safety protection for every driver, passenger and pedestrian. Here’s a look at how it can be broken into parts and use advanced “integrated” technology and scientific design to further protect travel. Safety.

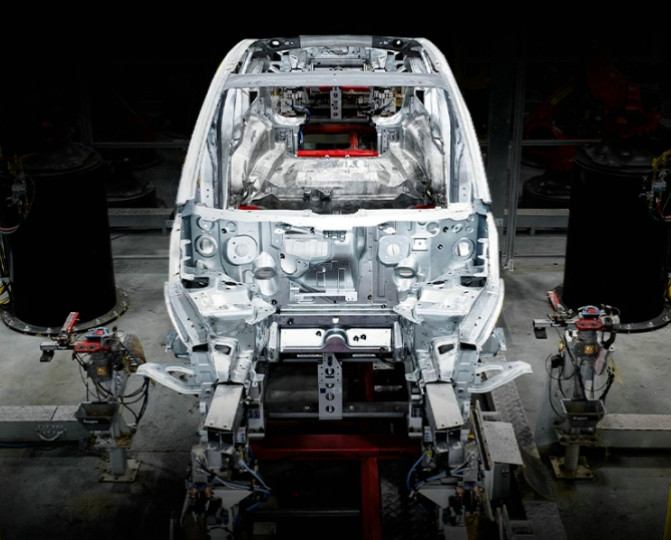

01 Tesla intelligent manufacturing integrated molding technology

Tesla's Shanghai Gigafactory is equipped with a 6,000-ton giant die-casting machine. Through the original integrated die-casting process, it avoids the separate production of parts and uses integrated castings to improve production efficiency and travel safety.

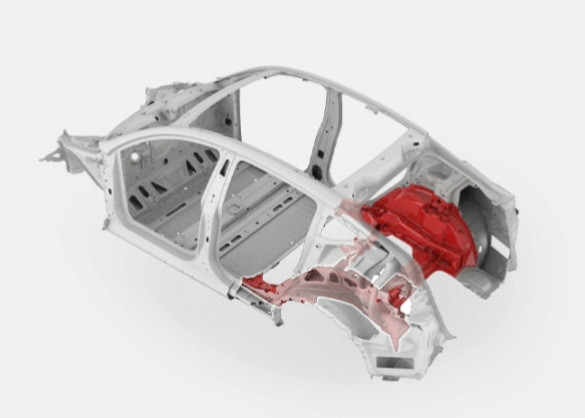

Model Y

The entire rear floor is formed in one piece, reducing approximately 70 welded parts.

Model Y rear bottom plate is integrally formed

Model 3

The side panels use newly designed one-piece hot-formed high-strength steel, which greatly improves the impact resistance of the body.

02 Another breakthrough in independent research and development technology

The biggest problem faced in manufacturing large aluminum castings is that they are prone to deformation during heat treatment.

Tesla independently developed a special alloy material with ultra-high strength and durability that does not require heat treatment and can be directly die-cast, effectively preventing deformation and greatly saving production costs and energy consumption. Tesla always adheres to first principles and solves problems from the essence of things. It does not stick to improving existing things, but promotes integrated production with disruptive innovation.

03 Integrated integrated design to further strengthen passive safety

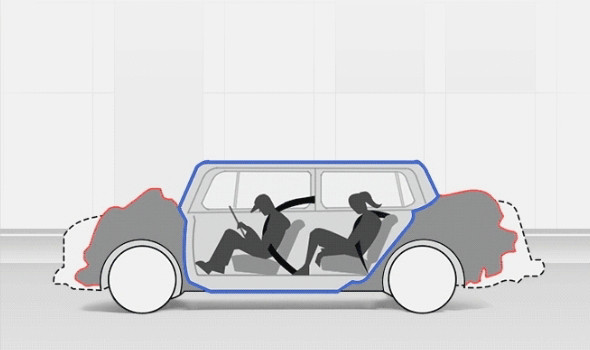

Passive safety refers to the vehicle's response mechanism after an accident. Tesla has taken this into consideration from the beginning of the design, aiming to absorb as much energy as possible from the impact. Based on the integrated molding technology, it uses its own Research advantages and multiple scientific designs ensure passenger safety to the greatest extent.

Progressive force-bearing, multi-path impact mitigation: When a frontal impact occurs, energy is absorbed step by step from the vehicle's front bumper to the body die-casting, and at the same time, the collision energy is effectively absorbed through multiple force transmission paths.

The force path designed by Tesla will push the vehicle away from the impact object when encountering an offset collision, ensuring that the vehicle does not always advance along the impact path, and then passes through the body structure to cope with the energy generated by the collision, minimizing the risk of driving The impact on the person.

04 Multi-pronged approach, design with safety first

In the event of a collision, Tesla uses a progressive force path and a solid body structure to ensure the integrity of the cabin to a greater extent. The lower center of gravity of the vehicle coupled with the excellent suspension system effectively reduces the risk of rollover. Scientifically and intelligently manufactured, it protects driving safety in all aspects.

Using leading technology to protect travel safety, Tesla continues to accelerate the integration process and explore more possibilities for new energy vehicles.

The above is the full content of How safe is Tesla?