Is BYD still leading in technology in 2024?

In 2023, BYD was undoubtedly the most successful Chinese brand, with sales expected to exceed 3 million vehicles. BYD's success cannot be separated from technological breakthroughs, but other domestic competitors have also reported success in new energy technology.

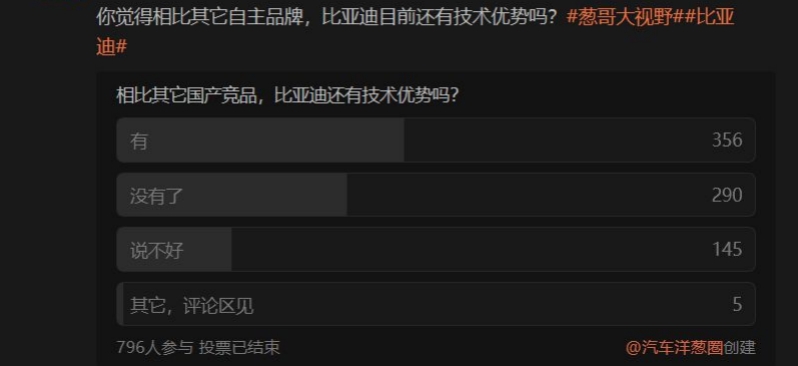

So, we initiated a vote on Weibo: "Do you think BYD still has technological advantages?" The result was that more friends disagreed and spoke ill of it than those who held a positive attitude.

In that case, let me share my own opinion: BYD's technology has been leading for a long time, but now it is being chased and diluted by a group of competitors, and it is not easy to say that it is leading again. Let's talk about three aspects together.

01. Electric drive system

BYD has launched two industry-leading electric drive systems, among which in the hybrid field, the EHS electric hybrid system used by DM-i; In the pure electric field, it is the eight in one electric drive used by the seal.

Let's first talk about the EHS used by DM-i. The reason for mentioning it here is because of its flat wire motor. Electric motors can be divided into circular wire motors and flat wire motors, among which flat wire motors are more advanced, with higher power density, better heat dissipation performance, and smaller size.

However, for a long time in the past, only foreign companies had the research and production capacity of flat wire motors, until BYD successfully developed flat wire motors for DM-i.

DM-i was officially released by BYD in early 2021. The motor used in its EHS hybrid system uses 6-layer flat wire winding and rotor direct injection cooling technology, which are also very mainstream in today's view.

You may not have much concept about these things, but what if I say its maximum speed can reach 16000 rpm and maximum efficiency can reach 97.5%? This was an absolute top level in the past, and it doesn't look bad now.

In addition, EHS also used BYD's self-developed IGBT 4.0. This power semiconductor module not only has low loss, strong heat dissipation, good overcurrent ability, but also very good reliability, making it a star product in the automotive industry at that time.

However, flat wire motors have become the mainstream of the industry today, and their performance and efficiency are also rapidly increasing. For example, the recently launched Shuzhi electric drive by Changan Qiyuan uses a self-developed 10 layer hairpin flat wire oil cooled P3 motor.

This should be the second 10 layer flat wire motor in the industry to be used for mass production of passenger cars after Tesla. In theory, the higher the number of flat wire layers, the higher the power density of the motor, but the difficulty of research and manufacturing will also increase accordingly.

But in my opinion, BYD has the ability to make 10 layer flat wires. The original intention of the 6-layer flat wire motor should be to balance cost and low-speed conditions, after all, the DM-i equipped cars are affordable grocery cars.

However, this reason is definitely not very feasible now, because the positioning and pricing of several new models launched by Changan Qiyuan are also very affordable, such as the A05. The positioning and pricing of this car are similar to the Qin DM-i, and I happened to test drive it briefly before, and the experience was very good.

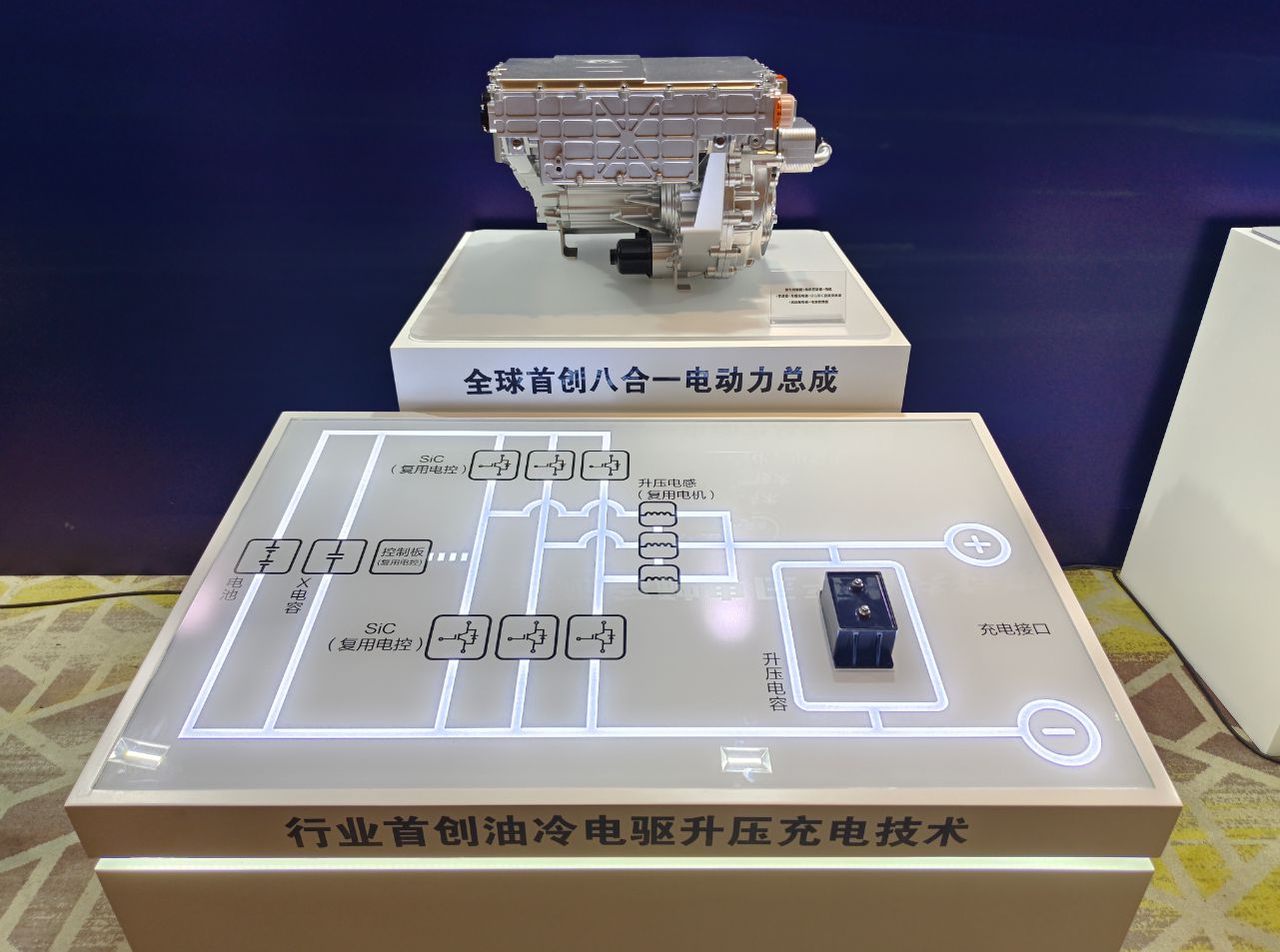

Next is the eight in one electric drive system applied to pure electricity. This electric drive system is very advanced in two aspects: one is its ultra-high integration, and the other is the application of SiC, which has brought BYD's electric drive into the 800V era.

Eight in one is not difficult to understand, it is to integrate the original eight independent system components together. The higher the integration, the lower the weight, and the lower the space occupancy rate, which improves the handling experience and passenger space.

BYD's eight in one electric drive was released at the end of 2022. Prior to this, the integration level of electric drives from competitors was generally lower than that of BYD, and some even remained in a relatively primitive three in one stage.

However, "multi in one" is also a mainstream trend in the industry. Nowadays, in addition to BYD, Zero Run has also launched its self-developed eight in one electric drive system, and even Dongfeng has launched a ten in one Mach electric drive.

In addition, 800V, especially the full range 800V, has become a "standard" for first tier car companies after the Xiaopeng G9. SiC silicon carbide power devices have been widely used, which has further enabled competitors to seize BYD's voice.

02. Blade battery

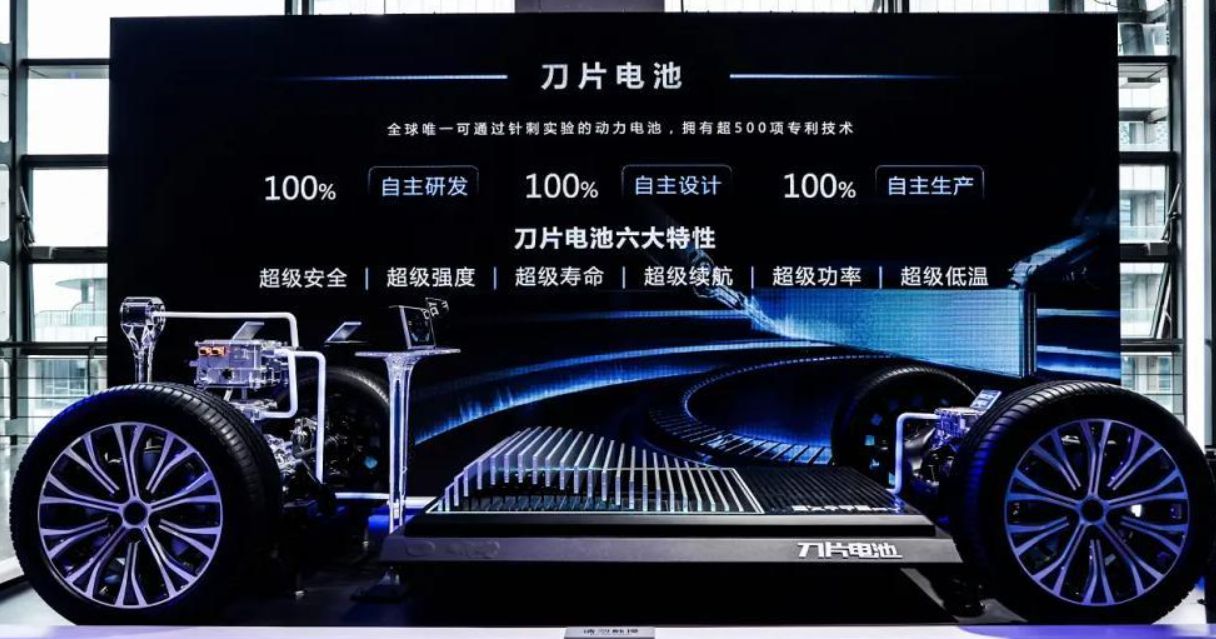

I don't need to elaborate on this, everyone has heard of its reputation.

In the era when lithium iron phosphate was suspended and beaten by ternary lithium, blade batteries relied on a unique design concept to save the poor energy density of lithium iron phosphate and had the capital to compete with ternary lithium.

For example, the energy density of a single blade cell is 180, while the energy density of the entire battery pack is 140; The energy density of a single cell of Tesla Model Y ternary lithium is 260, while the entire battery pack is 180- the integrated energy density loss is completely different.

In addition, the surface area of blade cells is larger than that of cylindrical batteries of the same era. Coupled with pole ear designs on both sides, its heat dissipation performance has also improved, which is helpful for improving battery life, safety, and endurance.

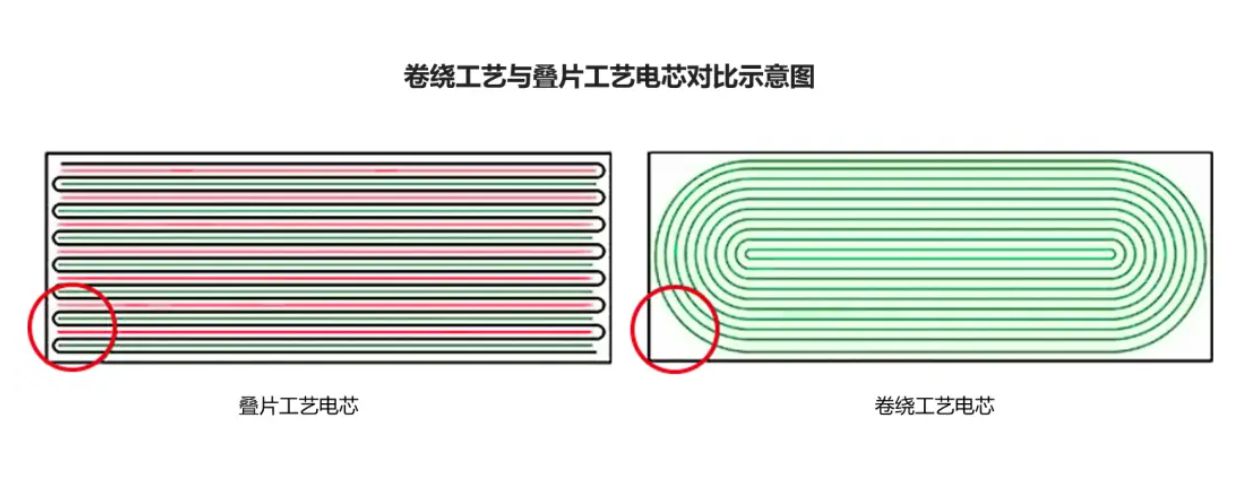

Moreover, the blade battery cell is one of the earliest mass-produced lamination processes in China, which can significantly improve the energy density, lifespan, and safety performance of the battery cell. However, it requires more advanced, efficient, and mature production lines and process support.

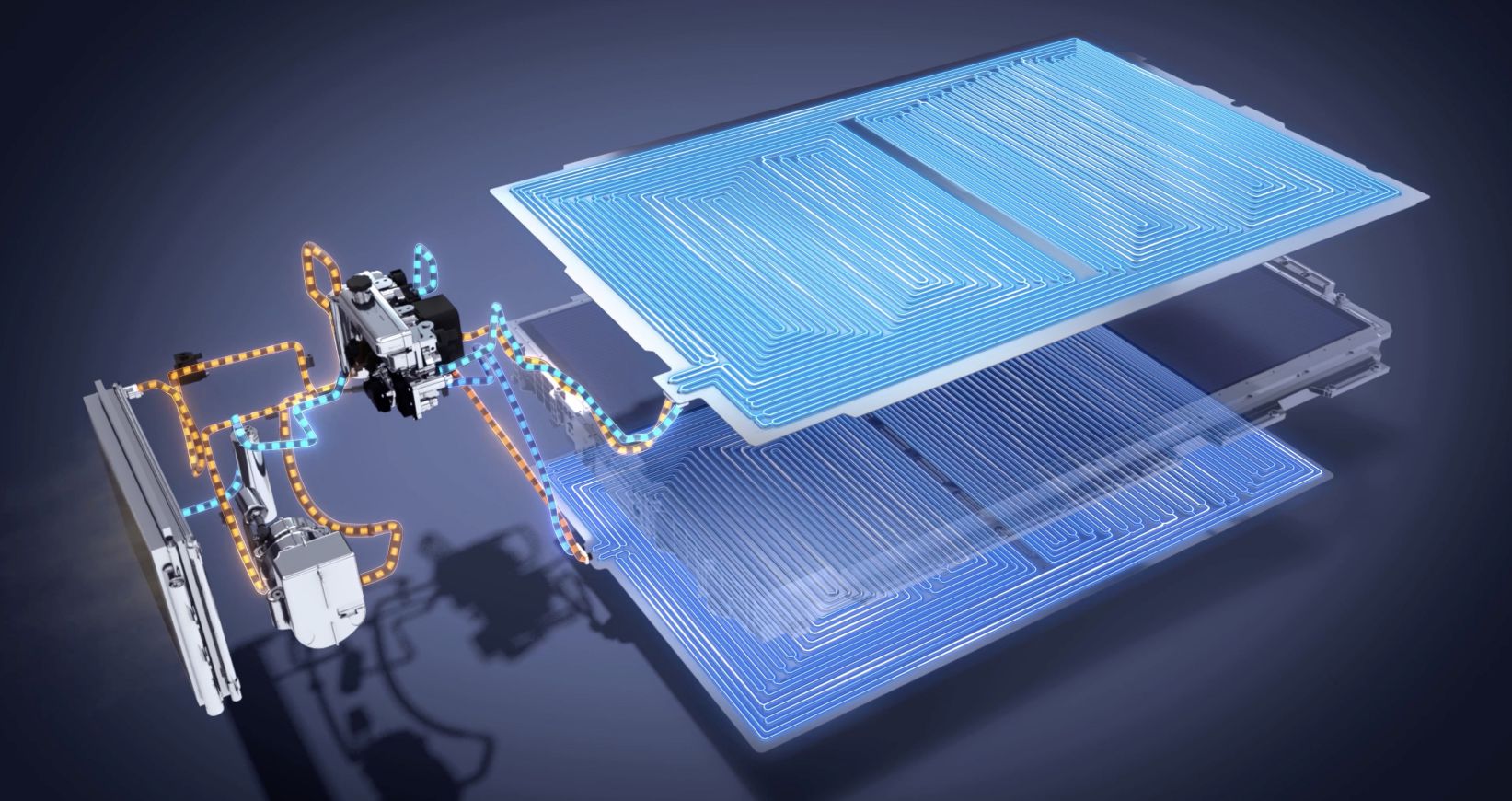

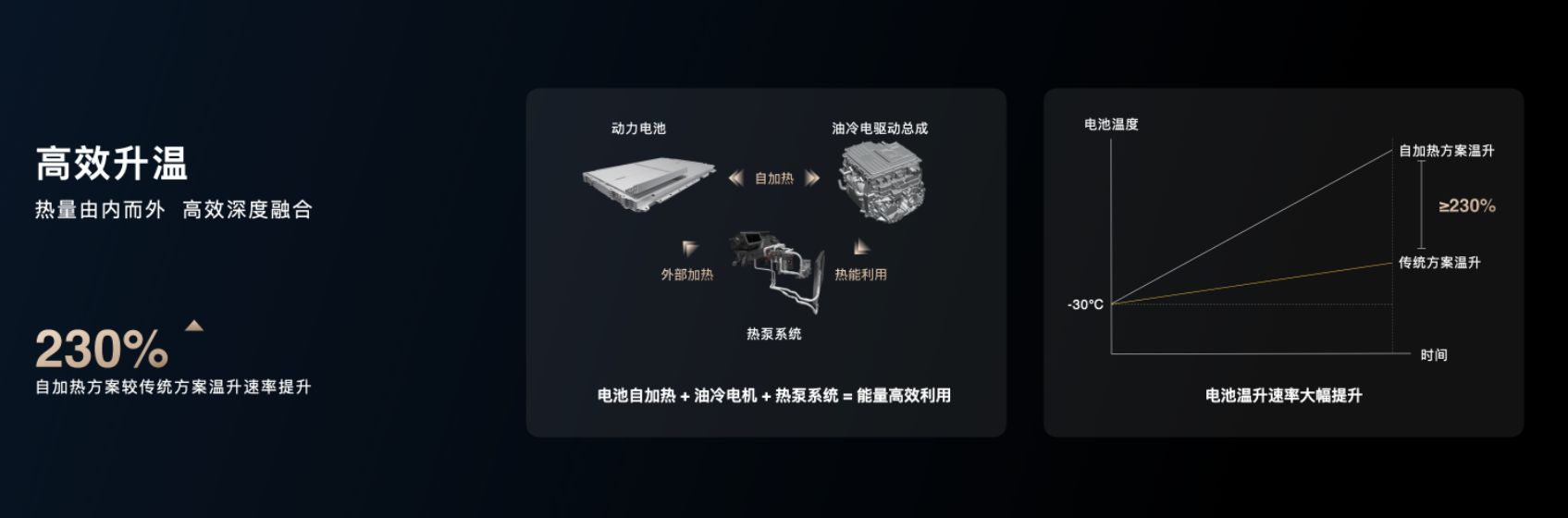

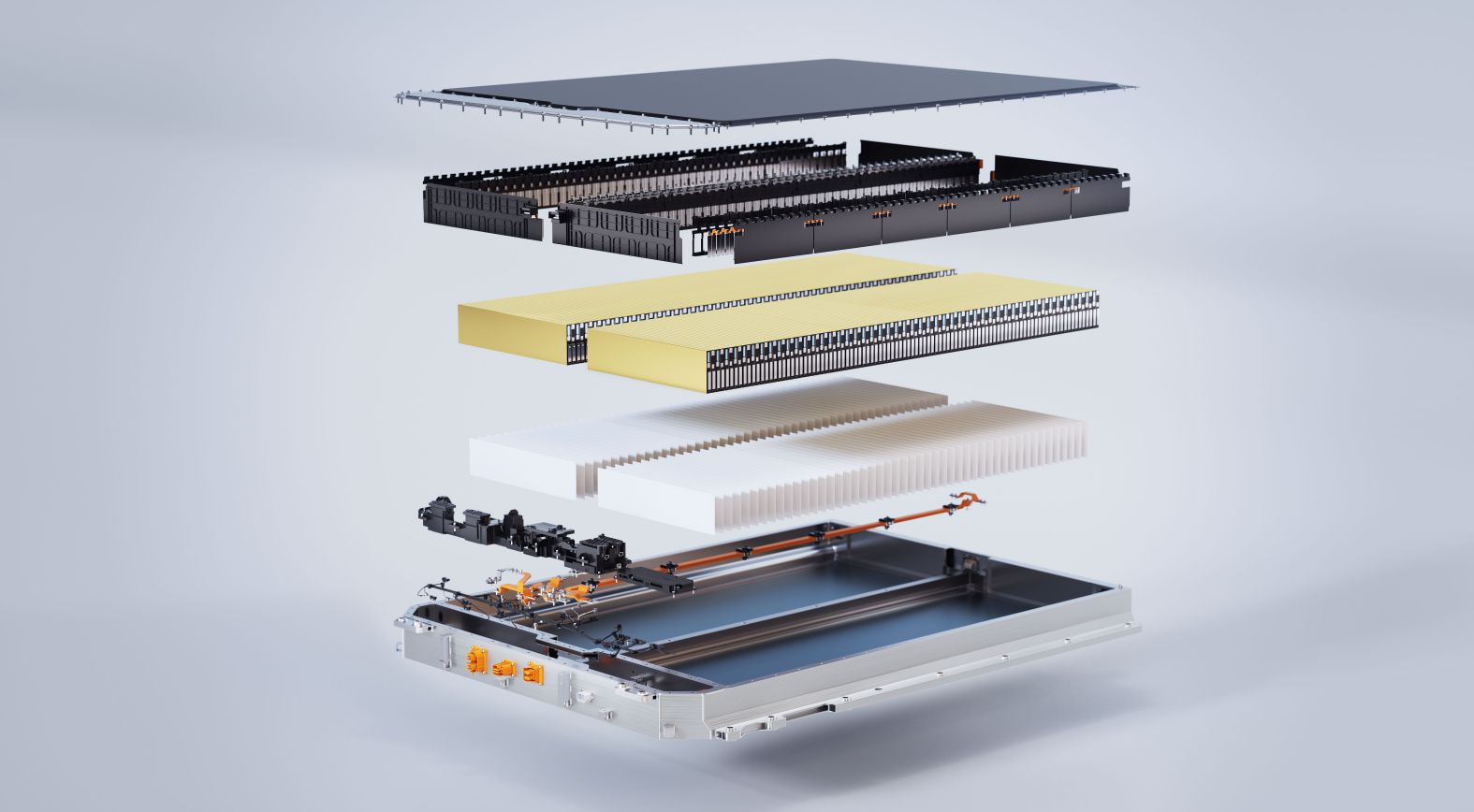

Not finished yet, the thermal management of the blades is also very advanced, such as upper and lower double-layer liquid cooling plates and pulse self heating technology. These two technologies can more efficiently and intelligently control the battery temperature during charging and daily use, and the working noise is very low, which does not affect ride comfort or driving power response.

But starting from this year, lithium iron phosphate batteries have launched a comprehensive counterattack. Ningde Era's Shenxing battery, Honeycomb Energy's Dragon Scale Armor battery, and Extreme Krypton's Golden Brick battery have been released successively, all of which are very attractive. We will discuss them in detail in a future issue.

Let me briefly talk about the BRICS battery. I just attended their press conference a while ago and was very impressed: its charging rate reached 4.5C, the maximum charging power reached 500kW, and the peak discharge rate also reached 16C.

In other words, whether in terms of charging speed at home or power release at the performance level, BRICS batteries have truly reached or even surpassed mainstream ternary lithium batteries! This is not even the high safety feature inherent in lithium iron phosphate!

Next is Dragon Scale Armor Battery, and Honeycomb Energy is also one of the earliest domestic enterprises to master the cell stacking process, and has developed to the third generation with very mature technology; In terms of thermal management, there is also a design of upper and lower double-layer liquid cooling plates.

In addition, companies such as Changan and CATL have also introduced similar technologies and patents for the pulse self heating technology mentioned earlier. However, BYD also stated that their self heating technology still holds an advantage.

In summary, in the face of these epic aftershocks, the status of blade batteries in the world is precarious. However, recently I have also heard some rumors that BYD will release the second generation blade battery with comprehensive performance upgrades this year, and I am very much looking forward to it.

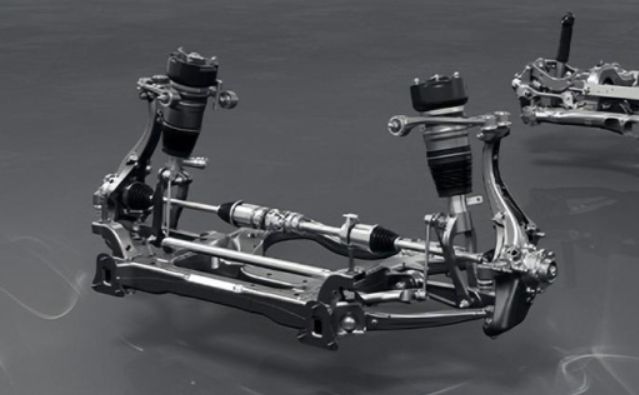

03. Yunnian chassis

The Yunnian chassis is also very advanced because it is one of the few active chassis technologies for passenger cars with large-scale production capabilities. Earlier this year, I also experienced the Tengshi N7 equipped with Yunnian A. Even though the preview function had not yet been launched, its overall vibration filtering experience was very good.

In my opinion, the leadership of Yunnian lies not in the improvement of hardware, but more in the software level, such as the upgrade of the vehicle's electronic and electrical architecture.

Within the control domain where Yunnian is located, there are independent computing platforms and perception and control algorithms, which can also connect the perception hardware of intelligent driving. This is just like in martial arts novels, where martial artists are connected to the Ren and Du meridians.

However, Huawei later launched the Touareg chassis. This is also a rare set of active chassis technology, and I personally believe that the Touareg is better than the Yunnian in terms of hardware and software.

For example, on the hardware level, the Zhijie S7 equipped with the Touareg adopts a double wishbone structure with front upper and lower ball joints, while the Tengshi N7 equipped with the Yunnian A adopts a standard double wishbone structure.

I have briefly commented on this suspension system in the previous content: it has many hard points, high upper limit adjustment, but also high difficulty. It takes a long time to adjust, but not enough. In addition to the Smart S7, the Quest M9 also uses this structure.

At the software level, the concept of iDVP electronic and electrical architecture, which is coordinated with Tulingda, is also very advanced. Its logic of regional access+central control is similar to the centralized power+six departments and six departments system of the Ming Dynasty, which can enable multiple complex functions to collaborate quickly and efficiently.

In my opinion, the level of intelligent driving technology also affects the experience of active chassis technology. The combination of the two can maximize the driving and riding effects of the latter, fully leveraging the advantages of active chassis.

From this point of view, Huawei's ADS 2.0 is already recognized as the first tier level in China, while BYD's latest progress is the recently launched high-speed NOA of the Tengshi N7, which was also developed in collaboration with Momenta.

04. To summarize

The current automotive industry is too competitive. As a pioneer in the new energy field, BYD finds it difficult to maintain its technological leadership, as even the most advanced technology will be caught up and surpassed by its competitors every minute.

However, in my opinion, BYD has always been far ahead in one technology, which is "technology inclusiveness". BYD has been laying out in the new energy field for a long time and now has a high degree of vertical integration ability in the industry. Many core components can be self-developed and produced, which is a major advantage in cost control and production manufacturing.

The BYD "998" that can be seen everywhere in the streets and alleys is an example. It is difficult to say which technology of the DM-i is industry-leading, but each technology is in the mainstream position of the industry, with good experience and low price. Recently, it has been downgraded from "998" to "898", which is not more realistic than struggling with which technology is "far ahead"?

The above is the full content of Is BYD still leading in technology in 2024?